Ikoranabuhanga rya Diamond Gutema Ikoranabuhanga rizwi kandi guhuza tekinoroji yo guca ahagaragara. Nukoresha uburyo bwa electraplating cyangwa uburyo bwo guhuza diyama bwuzuye hejuru yicyuma, insinga ya diyama ikora hejuru yinkoni ya silicon cyangwa ingot ya silicon kugirango isuzugure, kugirango igere ku ngaruka zo gutema. Gukata diyama bifite ibiranga umuvuduko ukabije wo gukata, gucika intege cyane no gutakaza ibintu bike.

Kugeza ubu, isoko rimwe rya Crytal kuri Diamond Gukata Silicon Wafer byakiriwe neza, ariko nanone byahuye nabyo mu kuzamura, muri bo velvet yera nikibazo gikunze kugaragara. Urebye ibi, iyi mpapuro yibanda kuburyo bwo kwirinda gukata diyama monocrystalline silicon wafer velvet ikibazo cyera.

Inzira yo gusukura ya diyama yo gutema monocrystalline silicon wafer ni ugukuraho umuyoboro wa silicon waciwe nigikoresho cyimashini kuva mu isahani ya resin, kandi usukure wafer wa silicon. Ibikoresho byogusukura ahanini ni imashini ibanziriza isuku (imashini ya stamming) nimashini isukura. Inzira nyamukuru yo gukora isuku yimashini ibanziriza isuku ni: Kugaburira-Spray-sprasonic isuku-stasonic isukuye-amazi meza yoza. Inzira nyamukuru yo gukora isuku yimashini isuku ni: Kugaburira-amazi meza yoza-alkali gukaraba-alkali gukaraba-kurandura amazi (guterura buhoro (kugaburira-kugaburira.

Ihame rya Cortstal Velveal Velvet

Monocrystalline silicon wafer ni ikintu kiranga kanseri ya anisotropic ya monocrystalline silicon wafer. Ihame reaction nigipimo gikurikira cyo kugereranya imiti:

Si + 2naoh + H2O = na2sio3 + 2h2 ↑

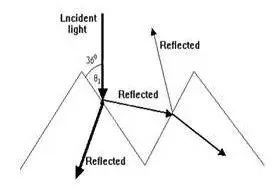

Muri rusange, inzira yo gushiraho suede ni: Naoh Igisubizo cyigipimo gitandukanye cya Crystal Hejuru ya Crystal, (100), bityo (100) kuri ruswa ya monocropique nyuma yubuso bwa anisotropic, amaherezo yashizweho hejuru . After the structure is formed, when the light is incident to the pyramid slope at a certain Angle, the light will be reflected to the slope at another Angle, forming a secondary or more absorption, thus reducing the reflectivity on the surface of the silicon wafer , ni ukuvuga, ingaruka zoroheje (reba ishusho ya 2). Ibyiza nubunini nuburyo bumwe bwa "Pyramide", niko urushaho uruhare runini mu mutego, naho hasi hejuru ya Wafer wa Silicon.

Igishushanyo 1: MicroMorphology of monocrystalline silicon wafer nyuma yumusaruro wa alkali

Igishushanyo 2: Ihame ry'umutego rya "Pyramide"

Isesengura rya kirisiti rimwe

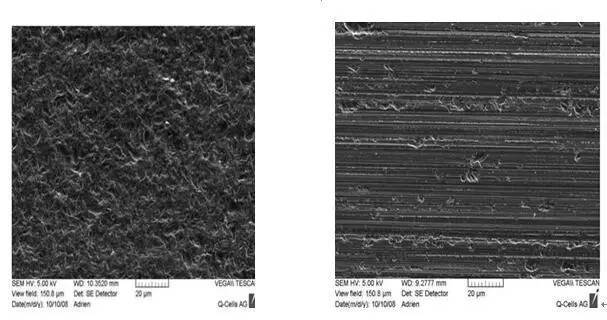

Mu gusikana microscope ya electron kuri Silicon Yera, wasangaga ko imishinga mireri ya piramide ya Waferi yera muri ako gace ko itagize uruhare runini, kandi ubuso "ibisigisigi bya" ibishashara ", mu gihe imiterere ya Pyramide ya Suede Mu gace keza ko wafen imwe ya silicon yashizweho neza (reba Ishusho 3). Niba hari ibisigazwa hejuru ya monocrystalline silicon wafer Agace hamwe nuburyo bwo hejuru ugereranije nubusanzwe mubiboneka bigaragara ko ari umweru. Nkuko bigaragara muburyo bwo gukwirakwiza ahantu hera, ntabwo isanzwe cyangwa isanzwe ahantu hanini, ariko ahantu habi. Bikwiye kuba ko abapfumu baho wazifesiye ya silicon batasukuwe, cyangwa imiterere yubuso bwa Silicon Wafer iterwa no kwanduza kabiri.

Igicapo 3: Kugereranya ibikorwa bya microse yo mukarere muri velet yera ya silicon yera

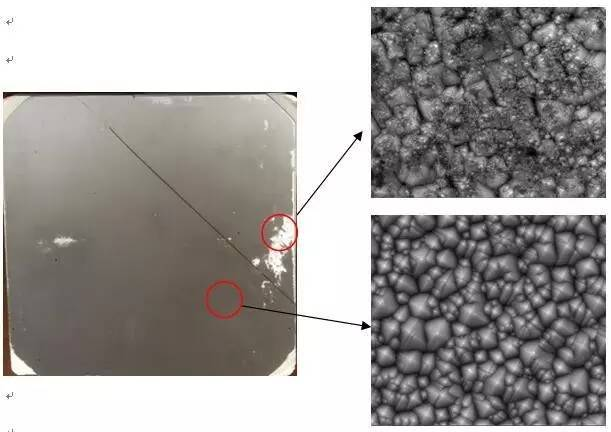

Ubuso bwa diyama yaciwe muri silicon byoroshye kandi ibyangiritse ni bito (nkuko bigaragara ku gishushanyo cya 4). Ugereranije na silicon silicon wafen, umuvuduko wa alkali na diyama waciwe muri silicon wafer ya licocrystalline Silicon Wafer.

Igishushanyo 4: (a) micrograph yo hejuru ya minisiteri ya minisiteri yagabanije silicon

Inkomoko nyamukuru ya diamant wire-gukata Silicon Wafer

. Gukata amazi hamwe nigikorwa cyiza gifite ubuhagarikwa ryiza, gutatanya no kubushobozi bworoshye bwo gusukura. Ubusanzwe abari basanzwe bafite imitungo myiza ya hydrophilic, byoroshye gusukura mubikorwa bya silicon wafer. Gukomeza gukomera no gukwirakwiza izishyingo mumazi bizabyara umubare munini wibifum, bikaviramo kugabanuka kwubukonje, bigira ingaruka kumikorere ikonje, hamwe nibibyimba bikomeye ndetse bikagira ingaruka zikomeye ku ikoreshwa. Kubwibyo, ubukonje bukoreshwa hamwe numukozi wa defoaming. Mu rwego rwo kwemeza imikorere ya defoamus, ubudozi gakondo na polyreet mubisanzwe ni hydrophilic mbi. Gukemuwe mumazi biroroshye cyane kwanga no kuguma hejuru ya wafer wa silicon mugihe cyogusukura cyakurikiyeho, bikavamo ikibazo cyambayeho. Kandi ntabwo ihuye neza nibice byingenzi bya coolant, kubwibyo, bigomba gukorwa mubice bibiri, ibice byingenzi hamwe nibibazo byo gukoresha, ukurikije ibikorwa bidashoboka, bidashoboka kugenzura neza Gukoresha no Gupima Abakozi ba Antifoam, barashobora kwemerera byoroshye kugirango barengere ibisigazwa bya kanoaming, biganisha ku kwiyongera kwa Silicon Ibikoresho rero, ibyinshi mubikonje byo murugo byose bikoresha iyi sisitemu ya formula; Undi gukonjesha akoresha umukozi mushya wa defoaming, arashobora guhuzwa neza nibice byingenzi, nta byo byongeweho, birashobora no gukoresha neza imikoreshereze myinshi, imyitozo nayo iboneye cyane, ifite uburyo bukwiye bwo gukora isuku, bwayo Ibisigisigi birashobora kugenzurwa kurwego rwo hasi cyane, mubuyapani nabayobozi bake murugo bafata iyi gahunda yo kurema, ariko, kubera ikiguzi cyacyo cyibanze, inyungu zayo ntabwo bigaragara.

. insinga yatangiye gukata kumwanya wa reberi na resin, kuva muri silicon inkoni ya silicon hamwe nibicuruzwa byayo bya epoxy, ni 95 ℃, niba byoroshye kumurongo wa reberi cyangwa resin isahani iri hasi, irashobora gushyuha byoroshye mugihe cyo gukata no gutuma byoroshye kandi bishonga, bitera umutsima wa diyama, cyangwa ibirango bya silicon byakiriwe kandi Yandujwe na resin, yigeze kumufata, biragoye cyane guhaza, kwanduza ahabigere hafi yinkombe ya silicon wafer wafer wafen.

. na diyama yo gutema ubunini bwa silicon ubunini bwa silicon buganisha kubyo byoroshye kubyamamaza hejuru ya silicon hejuru, bituma bigorana. Kubwibyo, menya neza kandi ubuziranenge bwa coolant no kugabanya ifu ikubiyemo ubukonje.

. Umurongo wuzuye, gukata gukonje na minisiteri bifite itandukaniro rinini, bityo rero inzira ihuye, umukozi wa Agent, formula, etmula, nibindi bigomba kuba kubice bya diyama bihindura. Isuku yingenzi ni ikintu cyingenzi, umukozi wambere wamagegukijwe. inzira yo gukora isuku. Nkuko byavuzwe haruguru, igihangano cyumukozi wa defoaming ntigikenewe mugukata kwa mirtar.

.

Gabanya ikibazo cyo gukora umusatsi wa velet yera bigaragara

.

.

.

.

. Muri icyo gihe, birashobora kandi kongera iterambere ry'ubushyuhe bw'amazi, gutemba nigihe mugihe cyo gukaraba mbere, kugirango umenye neza ko ifu ya silicon yogejwe mugihe

.

. .

.

. Ihame ryayo rirasa nigisubizo cya SC1 gisukuye (kizwi cyane nkamazi 1) ya semiconductor silicon wafer. Mechanism yayo: Filime ya Okiside kuri Silicon Wafer yakozwe nimvururu za H2O2, zikangirwa na Naoh, kandi okiside nimbuto zibaho inshuro nyinshi. Kubwibyo, ibice bifatanye nifu ya silicon, resin, icyuma, nibindi) bigwa mumazi yoza hamwe na ruswa; Kubera okiside ya H2O2, ibintu kama ku buso bwa feri birabonwa muri CO2, H2O hanyuma ikurwaho. Iyi nzira yo gukora isuku yabaye silicon waptureurs akoresheje iyi nzira kugirango iture isuku ya monocrystalline clicon wafer, muri silicon wafer hamwe na tarivire yimodoka ya velvetstalline. Hariho kandi abakora bateri bakoresheje inzira isa neza yo gukora isuku, nabo bagenzura neza isura ya velvet yera. Birashobora kugaragara ko iyi nzira yogusukura yongewemo inzira ya silicon wafer kugirango ikureho ibisigazwa bya silicon kugirango ukemure neza ikibazo cyumusatsi wera kuri bateri.

umwanzuro

Kugeza ubu, Gukata insinga bya diyama byahindutse ikoranabuhanga nyamukuru yo gutunganya mu murima wa kirisiti imwe, ariko mu gihe cyo guteza imbere ikibazo cyo gukora ikirango cya silicon cyakajwe Wafer ifite imbaraga. Binyuze mu isesengura ryuzuye ryumuzungu, uterwa ahanini nibisigisigi hejuru ya silicon wafer. Kugirango urusheho gukumira ikibazo cya Silicon muri kanseri, iyi mpapuro isesengura isoko ishoboka yanduye umwanda wa Silicon Wafer, ndetse no kunoza ibyifuzo ningamba mubikorwa. Dukurikije umubare, akarere n'imiterere yibibanza byera, ibitera birashobora gusesengurwa no kunozwa. Birasabwa cyane cyane gukoresha hydrobden peroxide + inzira yo gusukura alkali. Ubunararibonye bwatsinze bwagaragaje ko bushobora kubuza neza ikibazo cya diyama Gukata Silicon Wafer, kugirango yerekane ibishishwa bya velvet, kugirango bibe umugeni rusange winganda hamwe nabakora.

Igihe cya nyuma: Gicurasi-30-2024